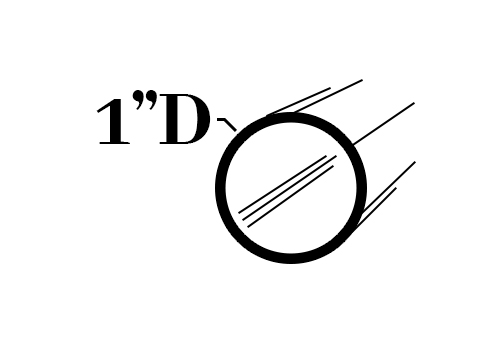

Featured Product – R16.05; 1x .050 Round Tube. Aluminum Tubes. DIMENSIONS: 1 OD w/.050 in. Wall.

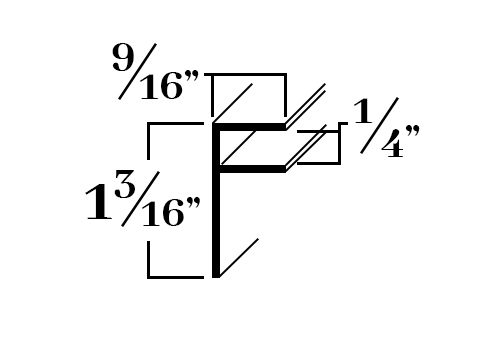

Featured Product – F250; For 1/4 in. Aluminum H,h,F,T & Z Channels. DIMENSIONS: For 1/4 in. material (.255 in. open).

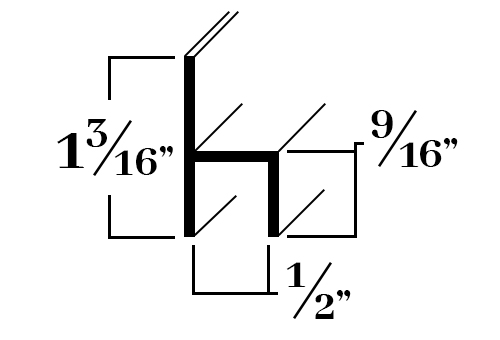

Featured Product – H500; For 1/2 in. Aluminum H,h,F,T & Z Channels. DIMENSIONS: For 1/2 in. material (.505 in. open).

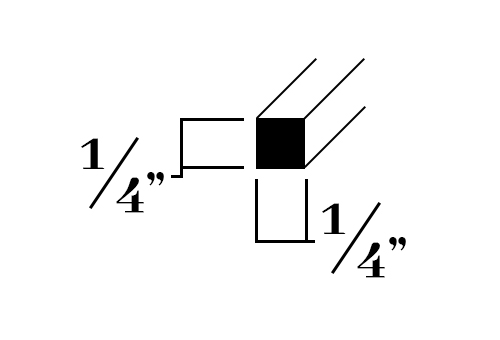

Featured Product – BS04; 1/4 in. Square. Aluminum Solid Stock. DIMENSIONS: 1/4 in.

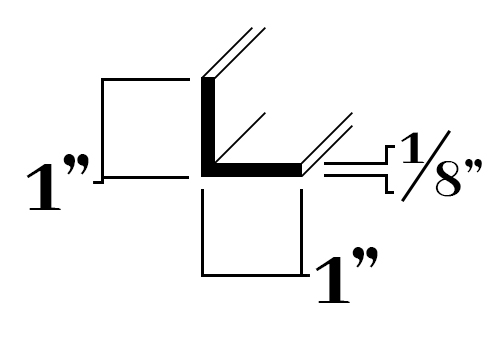

Featured Product – A416; 1 x 1/8 in. Aluminum Angles. DIMENSIONS: 1 in. x 1 in. x 1/8 in.

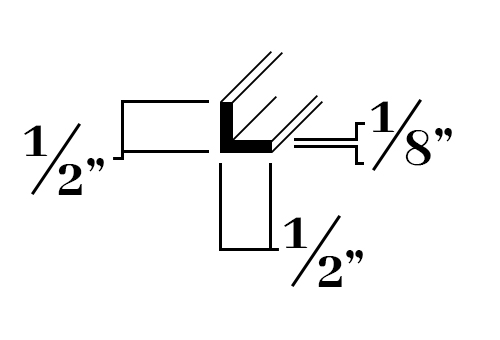

Featured Product – A408; 1/2 x 1/8 in. Aluminum Angles. DIMENSIONS: 1/2 in. x 1/2 in. x 1/8 in.

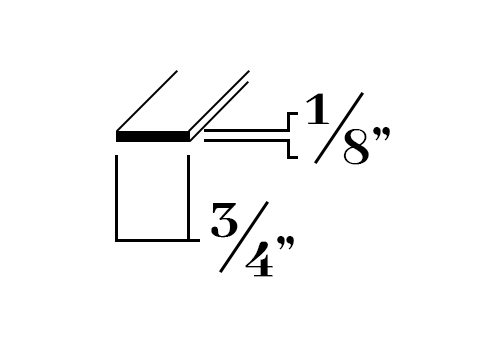

Featured Product – B412; 3/4 x 1/8 in. Aluminum Solid Stock. DIMENSIONS: 3/4 in. x 1/8 in.

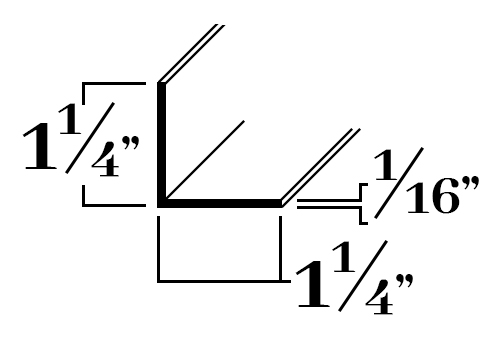

Featured Product – A220; 1¼x 1/16 in. Aluminum Angles. DIMENSIONS: 1¼ in. x 1¼ in. x 1/16 in.

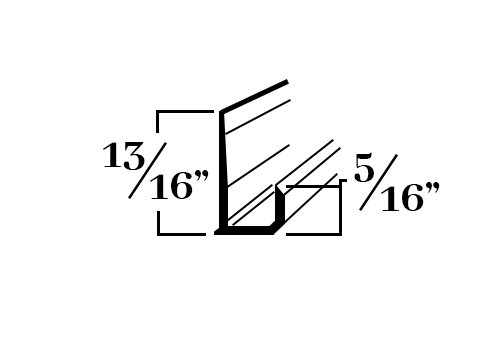

Featured Product – G851; Mirror Lower ‘J’ Channel. Aluminum Caps, Coves & Mirror Trim. DIMENSIONS: For 1/4″ Mirror.

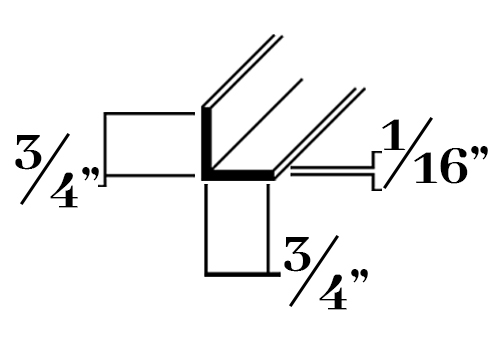

Featured Product – A212; 3/4 x 1/16 in. Aluminum Angles. DIMENSIONS: 3/4 in. x 3/4 in. x 1/16 in.